AI/ML & Vision Based Inspection Solutions

Typical challenges in Manual & Semi-Automated Quality Inspection:

With the high pace of growth in manufacturing, several supply chain issues arise, of which quality (and regulatory approval) of the products is the most critical. Many manufacturers – big & small – still use manual and semi-automated quality inspection processes, which acts as supply-chain bottleneck and huge quality threat

The challenges posed by manual and semi-automated quality inspection cannot be overstated given the regulatory, financial & public relations implications of poor quality, especially for products like food, beverage, drugs, medical devices, auto components, electronics, etc. While companies are looking to fully automate their inspection processes, most existing solutions are very expensive, can not adapt to the range of products in the market and lack the flexibility required for different product lines.

Industries Served

- Automotive

- Pharmaceutical

- Machinery

- FMCG

Thingularity Solutions

Thingularity works with leading technology partners in the field of AI/ML & Vision based inspection solutions to offer affordable, fully-automated, and high-throughput solutions for the following industries applications

Our automated Inspection solutions employ proprietary and industry-best approaches & components and provide the following benefits

- High speed, 100% automated inspection at the rate of several components per minute

- AI & ML based deep learning tech that learns and adapts to a wide range of products

- Quality Insights & manufacturing stats and at one place

- Eliminates Human Error and costs associated

- Machine Vision technology with latest image processing algorithms to identify visual defects

- Optics & Lighting to ensure accurate image processing

- ‘Good’ and ‘Bad’ or Other categories bifurcation

- Real Time Control and visibility of operation

Bottling Inspection Solutions

Thingularity provides Bottling inspection solutions for the Pharmaceutical, Food & Beverage, & FMCG Industry:

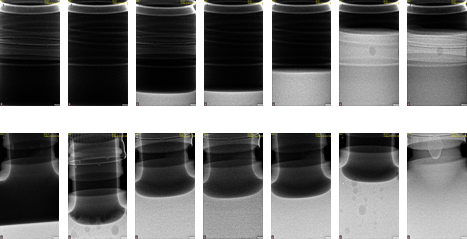

Opaque Container Inspection System:

This solution inspects the fill-level and detects any foreign body in opaque containers. It utilizes Automated X-ray Inspection (AXI) to automatically inspect aspects which are otherwise hidden from view. Wherever large numbers of very similar items are produced according to a defined standard, our AXI based Opaque Bottle Inspection System proves to be invaluable tool to ensure quality and to improve yield in processing and manufacturing.

Empty Bottle Inspection System:

Imperfect empty bottles and defects in them lead to stoppages in the filling line. By removing these defective bottles, higher efficiency in filling line can be achieved. Our solution utilizes a combination of machine vision and AI/ML algorithms along with robotics to helps detect imperfections like deformed bottles, cracks, chip-offs, and flaws in the mouth area, base and side wall in an automated fashion

Opaque Container Inspection System:

- Caps & Crowns Inspection

- Ampoule Inspection System & Vial Inspection System

- Dimension Check

- Cosmetic Check

- Fill Check

- Counting

- Bottle Orientation System

- Caser – with 6 Axis / SCARA Robot

- Caser – Cartesian Robot

- Un-Caser – Cartesian Robot

Packaging Inspection Solutions

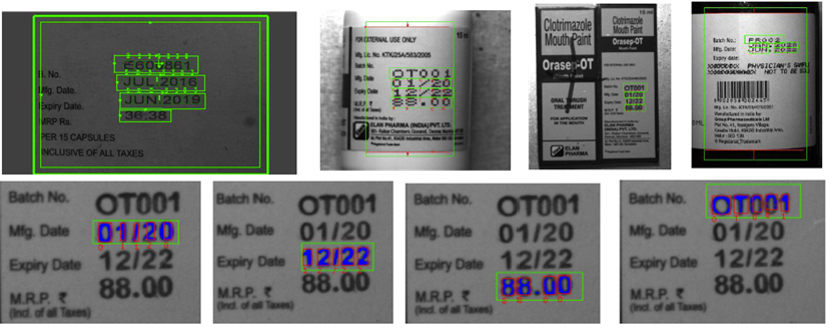

Label Inspection System: Container labels are key for a company’s branding and product information. Improperly applied labels spoil the aesthetics of the package, company credibility and product image.

Labels also carries important variable data like manufacturing date, expiry date, batch number and other plant data to help tracking and tracing in the event of a customer complaint and for regulatory purposes. Improper labels can lead to consumer complaints, dissatisfaction and regulatory challenges.

Our solution utilizes a combination of machine vision and AI/ML algorithms along with robotics to help detect & eliminate products with skewed labels, label shift and improper variable data.

Other Solutions Developed:

- Code Reading Solutions

- Blister Inspection

- Carton Inspection

- Bulk 2D Decoder

- Single Layer

- Multi-Layer

label orientation & variable data check, barcode & QR code verification

Automotive & Industrial Component Inspection Solutions

We have worked with on range of Automotive and Industrial components including:

- Bearings

- Bolts

- Connecting Rods

- Drawn Components

- Engines

- Hypoid Gear

- “O” Rings

- Pistons

- Punched Components

- Split Bearings

- Screws

- Stampings

- Timing Gears

- Washers

Solution Applications Include:

- Missing Parts Detection

- Assembly Integrity: Timing gear matching

- Valve Lock Check

- Machining Defect Check (burs)

- Contact Area Verification with Matching Gear

- Gear Angle Measurements

How our solutions are different

Competitor Products:

- Application limited to a few product specifications

- Each specification requires extensive customization which is expensive and time-consuming.

- Do not use deep learning algorithms to learn and adapt to specific requirements.

Our Solutions

- Quick and affordable change-over systems to adapt to different product specifications

- A cost saving to customers of 30 – 50% on both Capex and Opex

- Usage of deep-learning techniques to intelligently adapt to Indian requirements