Data Engineering Accelerator

Data Engineering Accelerator

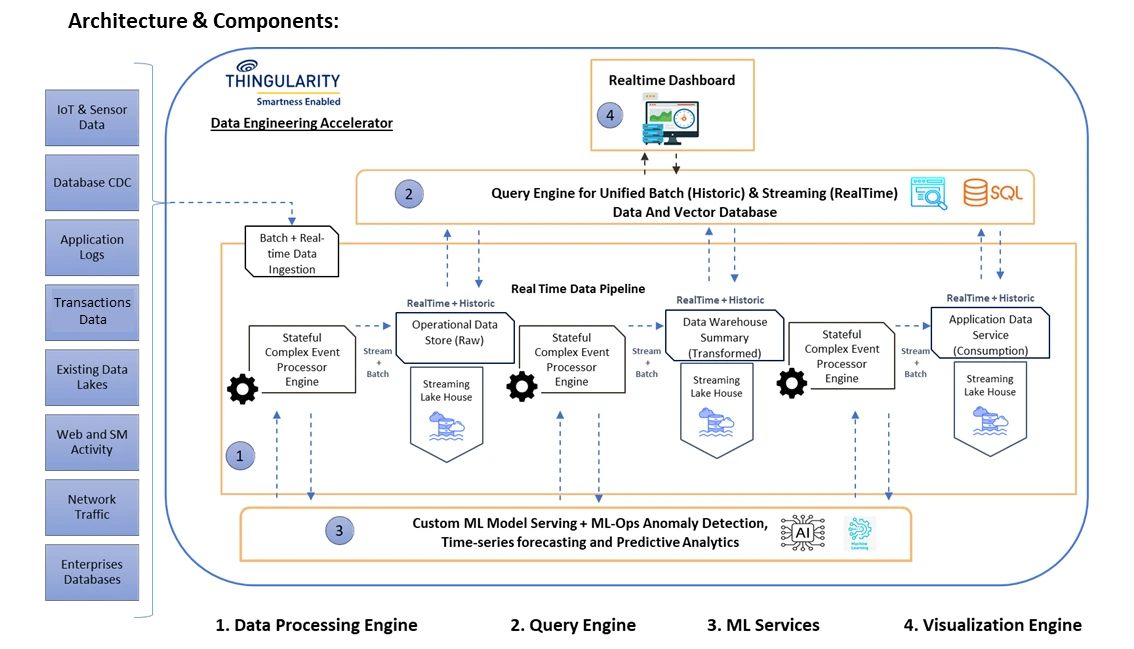

Thingularity’s Real-time Data Engineering Accelerator is a Single, Scalable, and Customizable Platform that turns raw streaming + batch data into actionable insights, in real time— driving both operational excellence and unlocking tangible business value. It enables accelerated development of data solutions with customizable modules.

It provides a framework for both real-time & batch and data enabling businesses to build, deploy, and manage data pipelines with ease, supercharging performance while eliminating data staleness.

Key Benefits:

- Real-Time, Instant Insights: Ultra Low query latency on both historical and live data, with real-time ingestion enabling event querying within 4–5 seconds.

- Scalable & High-Performance: Efficiently handles terabyte-scale batch loads and processes millions of events per second—without needing additional infrastructure.

- Simplified Architecture: Eliminate complex ETL pipelines with exactly-once semantics & federated querying across diverse sources – databases, streams, & querying

- Cost & Storage Efficiency: Save up to 50% on storage via optimized columnar formats and reduce operational costs by up to 40%.

- Flexible Deployment (BYOC): Deploy on any cloud or on-premise environment using Docker and Kubernetes

Business Use Cases

Connected Devices (HVAC, Appliances, Lights..)

- Usage Behavior & Analytics for Smart Sites : Real-time device event streams (from Lights, HVAC, Smart-Locks, Appliances, etc.) help infer routines, detect anomalies, and generate usage and energy consumption insights, which feed into dashboards and real-time recommendations and insights.

- Predictive Maintenance & Remaining Useful Life : Sensor data (vibration, temperature, pressure, etc.) are processed in real time to detect anomalies and compute predictive features. ML models estimate Remaining Useful Life (RUL), enabling proactive maintenance and reducing downtime, with results visualized on live dashboards.

- Warranty Intelligence & ROI Boost : By combining (sensor based) product usage data with claims history manufacturers can predict failures, prevent misuse, and remotely diagnose issues. This reduces service costs and wrongful claims while improving customer experience—turning warranty into a strategic value driver.

Industrial IoT/ Manufacturing

- Predictive Intelligence for Process Optimization: Leverages advanced capabilities including anomaly detection, predictive modeling, reinforcement learning, and digital twin simulations to provide deep insights into operational health. The system anticipates potential equipment failures, flags inefficiencies, and helps fine-tune processes—minimizing downtime and material waste while improving overall reliability and throughput.

- Edge/ Cloud Processing for Instant Insights: Combines high-performance data pipelines with seamless edge–cloud integration, enabling critical computations to happen where they’re most effective—either on the factory floor or in the cloud. Rapidly updated dashboards of assets and processes drives informed decision-making at every level.

- Operational Gains with Measurable Impact: Organizations benefit from measurable improvements, including reduced unplanned downtime, lower scrap rates, and higher production yields. Enhanced visibility through real-time dashboards and digital twins empowers teams to respond proactively, while data-driven intelligence helps optimize resource usage and reduce overall operating costs.

Smart Retail

- Boost Sales & Engagement: Streaming personalization and dynamic pricing pipelines increase conversions, drive higher revenue, and enhance loyalty by delivering targeted offers and promotions instantly.

- Optimize Costs & Experience: Intelligent real-time forecasting and fraud detection streamline inventory, reduce fraud losses, lower labor and fleet costs, and deliver seamless, reliable omnichannel customer experiences with instant insights.

- Minimize Stockouts & Waste: Real-time, shelf-level inventory analytics enable proactive replenishment, reducing lost sales and costly inventory distortion while improving operational efficiency.

- Shelf & Inventory Management: Real-time monitoring of shelf stock levels using IoT sensors (weight, RFID), and computer vision to detect empty/misplaced items and pricing errors. Minimizes out-of-stocks, reduces manual audits, and enables automated shelf-restocking, directly supporting better sales and customer satisfaction.

- Asset & Supply Chain Tracking: RFID, GPS, and IoT tags track pallets, containers, vehicles, and their environment (temperature, humidity), with video analytics monitoring load security. Provides full visibility into goods in transit, supports route optimization, ensures cold-chain compliance.